Earlier blogs have shown how difficult and deceptive it can be to relate energy consumed to work delivered. In this blog I would like to offer an example of this difficulty as it relates directly to ultrasonic transducers and cleaning. First of all, most (if not all) ultrasonic devices used for cleaning utilize a number … Continued

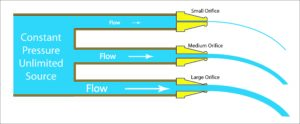

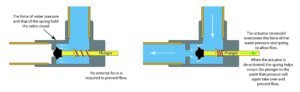

There is often a need in any system involving flow of a liquid to control the flow and/or pressure of that liquid. Since the two are different and yet inter-dependant, it can be confusing when trying to determine if flow control or pressure control is the intended goal and how it will be best be accomplished. Unfortunately, a wrong choice … Continued

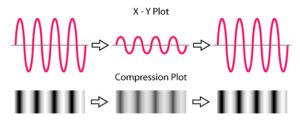

“Pulse” in ultrasonic terms simply means turning the ultrasonic energy on and off repeatedly in either a fixed or random pattern. At first it seems this would would be counter-productive to the goal of maximizing the ultrasonic cleaning effect. In fact, the blogs Ultrasonics – Ultrasonic Generators – What Is “Pulse” and Ultrasonics – Ultrasonic … Continued

Today’s blog will let you actually hear some of the qualities of sound that are important to successful ultrasonic cleaning. Since we humans can not actually hear ultrasound by definition, the sounds you hear will be “translated” into a sound range that we can hear. A good starting tone is 1,000 Hz. Sounds at 1,000 … Continued

The third of the basic types of manual valves is the “Gate” valve. This type of valve is probably not as familiar as the others but very important in the valve family. Although gate valves are made at least as small as 1/4″ to my knowledge, they are much more common in larger sizes. Almost … Continued

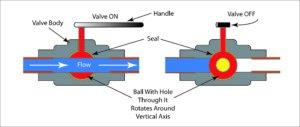

The ball valve is the most common example of a whole family of valves that include rotary valves, piston valves and other valves that use selective positioning of an inner core with one or more through-holes or cavities to direct flow from one or more inlet ports to one or more outlet ports. I realize that the … Continued

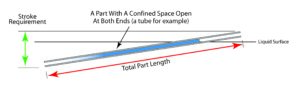

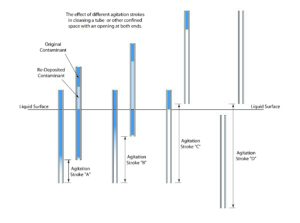

The preceding blog described the benefit of part agitation in a cleaning process. But, it is not always possible to provide adequate part agitation with a simple agitation of the part parallel to its central axis. With a little creativity, it is possible to provide effective agitation of even very long parts. In fact, there … Continued

Inadequate or improper agitation of parts in a cleaning tank is a common problem in industrial cleaning. Agitation, if properly applied, can be a very powerful aid to cleaning. The result of improperly applied agitation, however, can range from disappointing to disaster. The basic reason to agitate a part in a cleaning tank is to provide or … Continued

The specification of automated valves requires certain considerations that are not of concern with typical manually operated valves. The blog Valves – Automated Valves – What’s Different? provided a glimpse of automated valves with a very simple (but typical) example. There are, of course, innumerable variations used in the design of automated valves so the … Continued