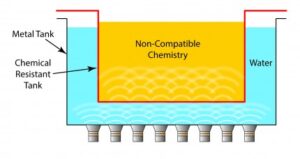

Maximum ultrasonic performance requires the most efficient transfer of ultrasonic vibrations from the ultrasonic transducers to the liquid in the process tank. This is generally accomplished by applying ultrasonic transducers directly to the exterior surfaces of a tank containing the process liquid. Transducer attachment techniques favor attachment to metals like stainless steel. What if the chemistry to be used … Continued

When a liquid or a gas flows uniformly and without turbulation, the result is called “laminar flow.” The most visual example of laminar flow for most of us are those arching water displays where perfectly shaped slugs of crystal clear water flys gracefully through the air from one point to another. When I first saw this effect at … Continued

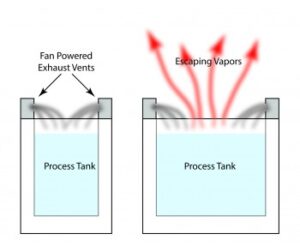

The environment in the area of an industrial cleaning system is often not a “healthy” one for personnel or equipment. Caustic and acidic cleaning chemistries rise as mist above cleaning processes along with humidity and heat. Although our first thought is to protect personnel from these hazards, the equipment can also suffer serious consequences as a … Continued

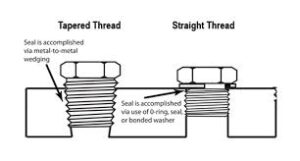

Wherever there are liquids there are leaks – it’s inevitable. Leaks, of course cost money in downtime and repair of industrial cleaning systems. So, you ask, what is the best defense against leaks. Most leaks occur where one piece of plumbing connects with another. A pipe to a valve, unions, connections to pumps and filters and … Continued

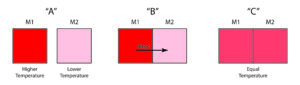

In ultrasonic cleaners, sound waves (vibration) originating from ultrasonic transducers must be efficiently transmitted into the cleaning liquid where they create cavitation bubbles which implode to enhance cleaning. The weak links in the path from the transducer to the cavitating liquid are typically the locations or “interfaces” where vibrations must be transmitted from one vibrating … Continued

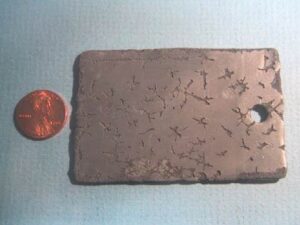

Ultrasonic cleaning is widely used for removing particles from surfaces. It is generally agreed that the high energy of implosions of cavitation bubbles break the bonds holding particles to the surface being cleaned and that liquid motion (streaming) carries the particles away once they have been dislodged. However, it is also well known that ultrasonic cavitation … Continued

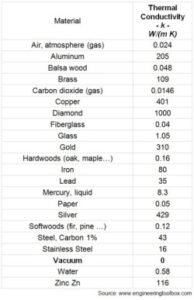

Heat conductivity is a measure of the ability of a material to transfer heat within itself. For example, if you heat one end of a short piece of copper wire, the heat is quickly distributed throughout the wire by conduction. This can be easily demonstrated using a short piece (1 to 2 inches) of heavy gage … Continued

Temperature has been identified as one of the important variables in cleaning – arguably the most important. So I thought it might be worth some time to develop a little understanding of heat – – especially how it is generated and transmitted. Heat is a form of energy. The amount of heat contained in an object … Continued

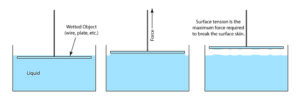

In the world of industrial cleaning technology we talk about surface tension a lot! So much so, in fact, that it is hard to enter into any discussion of cleaning without having the subject of surface tension arise. In cleaning chemistry, for example, we are always looking for lower surface tension to promote penetration of small surface features … Continued

Millipore testing is a very popular method of measuring and verifying part cleanliness. The procedure is described in the blog Millipore Testing. Although the procedures for Millipore testing are usually very well written and precise, there is still occasionally reason to question the results. So how do you make sure that the numbers are good? Since … Continued