I have spent considerable time on the blog disclosing and discussing a variety of cleanliness testing methods. A couple of tests that escaped earlier discussion, however, are the “white glove” test and the closely-related “swab” test. These tests are conducted by rubbing or wiping a surface using a white (usually cotton) glove or a cotton … Continued

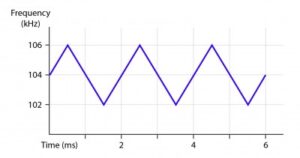

Note – The following blog is adapted from a paper recently written by Timothy Piazza, President of Blackstone-NEY ultrasonics and is re-printed here with his permission. This would probably be a good time to mention that guest blogs or suggestions for blog topics are always welcome. My email is jfuchs@ctgclean.com. FJF Blackstone~NEY Ultrasonics – Sweep … Continued

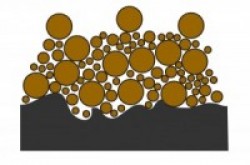

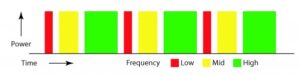

As described in a preceding blog, changing ultrasonic frequency has a demonstrated effect on the size of particles removed from a contaminated surface depending on frequency. Low frequencies produce large cavitation bubbles which implode with high energy. High energy implosions are able to dislodge relatively large particles from a surface. Higher frequencies produce smaller cavitation … Continued

The blog about maximizing the effect of multiple frequency ultrasonics explained in some detail the mechanics of cleaning using multiple ultrasonic frequencies and the benefits of sequencing through a series of frequencies multiple times to achieve maximum cleaning effect. This blog will further explore these benefits especially in cases where extended exposure of a part … Continued

In preceding blogs I have identified temperature as probably the single most important variable in a cleaning process. Devices that sense and control temperature, therefore, are a critical part of a cleaning system. Let’s take a quick look at a few of the types of temperature sensors that are available and suggest where each is applicable … Continued

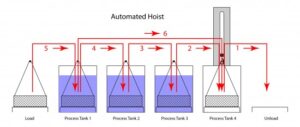

An automated hoist is probably the most commonly used means of moving parts through the steps of an automated immersion cleaning process. These hoists come in almost unlimited variations but have in common that they can move a basket or rack of parts in two dimensions along the axis of a multi-station cleaning system. Although the hoist suspension can … Continued

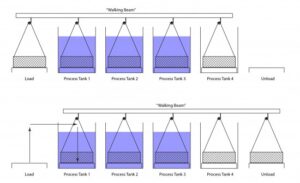

As in nearly any decision making process, one must consider the options available and the pros and cons of each for industrial parts cleaning automation. The next few blogs will describe some of the automation options that are available for industrial parts cleaning along with their benefits and potential shortfalls. Walking beams and “pushers” have … Continued

In the preceding blog we looked at the expansion and contraction of liquids as a means of measuring temperature. The expansion and contraction of solids (usually metals) is another way to measure temperature. Most solids expand and contract in a relatively linear way in response to temperature changes. In most cases, solids expand as they … Continued

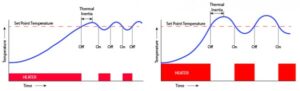

Meaningful temperature measurements depend on the selection of the proper sensors and controls and the proper placement of sensors to accurately measure the targeted temperature. For example, it was previously stated that bimetallic sensors, in most cases, ultimately sense the temperature of air around them. This makes bimetallic sensors a good choice for measuring air … Continued

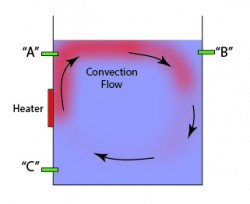

How Much Heat? – It is common for the design engineer to calculate the heat requirement for the tanks of a cleaning system based on the tank volume, the target operating temperature and the desired heat-up time from ambient temperature to operating temperature taking into account, of course, heat losses through the tank walls and … Continued