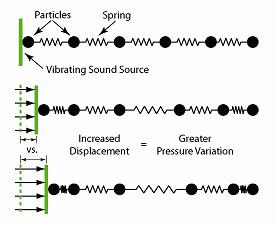

In the preceding post I explained how sound waves are created by a vibrating or pulsing source and how they are conducted by a sound conducting media. Amplitude, Frequency and Wavelength are characteristics of sound waves that will be important to understand as we progress to an understanding of ultrasonics. Today’s topic is amplitude. The above … Continued

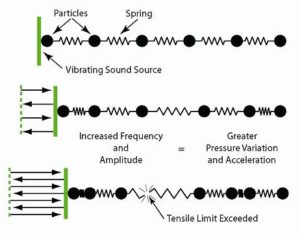

Two of the major variables in the production of mechanical vibration are frequency and amplitude. The consequences of frequency variation were discussed in a preceding blog. Today’s blog concentrates on amplitude and the power implications of varying either or both frequency and amplitude. As discussed in the blog titled Ultrasonics-Sound-Amplitude, the amplitude of a vibration … Continued

As Christmas is only a few days away, I would like to wish you a Happy Holiday Season on behalf of the Cleaning Technologies Group. I would also like to ask anyone who reads this to extend holiday greetings to everyone around you, especially those less fortunate. I, personally, am prone to “random acts of … Continued

Today’s blog is responding to two questions asked by readers. Both concern monitoring of ultrasonic transducer performance. Ralph Clendenin asks – “Is there a measurement of the frequency I need to be aware of during “good” operation I can check monthly that would show reduction in cleaning due to change in frequency?” Stephen Sharkey asks – … Continued

In the blog Cavitation 101, cavitation in liquids was described as the backbone of ultrasonic cleaning. Cavitation by itself, however, is not the end of the story. Although cavitation is the backbone, the real work is accomplished by the implosion of cavitation bubbles. Cavitation bubbles are, in essence, pockets of vacuum or vapor of the surrounding … Continued

Cavitation of liquid due to high amplitude ultrasonic vibration within the liquid is the backbone of ultrasonic cleaning. Liquids have the unique ability to cavitate. In order to cavitate, a material must exhibit three properties – It must be relatively inextensible and uncompressible. It can’t be able to stretch or expand or be compressed to significantly change … Continued

Today, the vast majority of transducers used for ultrasonic cleaning applications utilize the “piezoelectric” effect to transform electrical energy to mechanical motion. These devices are sometimes called “piezos” because they are driven by piezoelectric elements which are integral to the transducer. Piezoelectricity was discovered by Maria and Pierre Curie who also experimented with radioactivity and … Continued

At the heart of any ultrasonic transducer is a means to convert electrical energy into mechanical energy. The use of piezoelectric materials to do this was discussed in a previous blog. Today’s blog will describe how magnetostrictive materials can also be used to convert electrical energy into mechanical energy. Ultrasonic transducers using magnetostriction as a source of … Continued

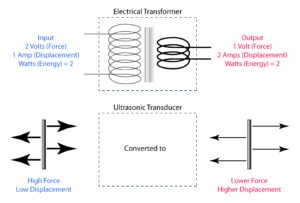

The piezoelectric and magnetostrictive effects which drive ultrasonic transducers are capable of creating considerable force but only minimal displacement. In order to produce sound waves of sufficient amplitude (displacement) to cause cavitation in a liquid, some means must be used to increase the displacement produced by the primary piezoelectric or magnetostrictive effect. In both cases, the key to doing … Continued

In an ultrasonic cleaning system, the device that provides the electrical energy to power the ultrasonic transducers is known as the ultrasonic “generator.” Basically, the ultrasonic generator converts electrical energy received from the power line into electrical energy with the proper frequency, voltage and amperage to power or “drive” the ultrasonic transducers. In most cases, … Continued