Currently browsing: Ultrasonic Cleaning

FOR IMMEDIATE RELEASE: Blackstone-NEY Ultrasonics Introduces the Stainless-Steel GMC Series Ultrasonic Cleaning System. May 2018 – Jamestown, NY Blackstone-NEY Ultrasonics, a division of Cleaning Technologies Group, LLC, is proud to introduce an innovation in cellular aqueous parts cleaning, offering a Stainless-Steel GMC Ultrasonic Cleaning System. The Stainless-Steel GMC is an optional package to achieve … Continued

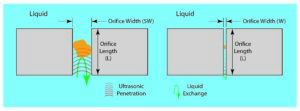

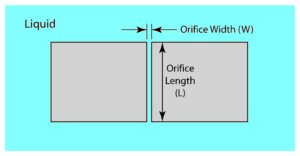

Dimensions of orifices and typical contaminant scenarios were discussed in preceding blogs. Today, let’s consider the role of ultrasonics in removing contaminants from orifices. First, we’ll consider the “classic” orifice consisting of a passageway through a solid. Then we’ll talk about some special cases which can have an impact on the ability of ultrasonics and … Continued

A few days ago, one of our customers asked one of our sales people what would seem like a very simple question. The question, in paraphrase, was – – “Do you know the relationship between ultrasonic frequency and the ability of ultrasonics to clean within a certain sized orifice.” Being a bit rushed when I received … Continued

What is ultrasonic cleaning and why is it so effective? Understanding ultrasonic cleaning begins with looking at the science behind it. Learn more.

The preceding post defined two dimensions of concern when considering cleaning orifices. Before moving on, let’s now consider how the various types of contamination that might be found in an orifice and how each affects the cleaning task. Liquids – Liquids are common contaminants in orifices. Liquid contamination can result from manufacturing operations but also … Continued

Liquid-borne acoustic energy in the frequency range between 350kHz and up to about 5MHz is finding growing usefulness in a number of cleaning applications which require processing of extremely delicate parts and assemblies to remove particles ranging from a few microns down to a fraction of a micron in size. This “megasonic” energy varies from … Continued