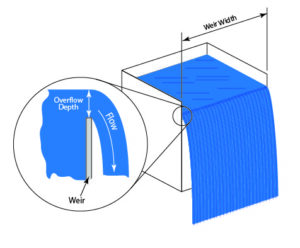

Overflow weirs are common features of industrial cleaning systems. Simply, a weir is much like a dam that holds back a river to form a lake. In the case of a cleaning system, the “lake” is usually a tank of liquid. The “dam” is formed as a portion of the lip of the tank is … Continued

Previous blogs have discussed the importance of rinsing as part of the overall cleaning process. Because of its importance, many schemes have been devised to assure that parts are adequately rinsed after cleaning. Most of these schemes embrace the “more is better” concept which often leads to overkill as there is often no practical way … Continued

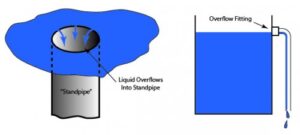

Overflow weirs have specific purposes as they are utilized in industrial cleaning equipment. Also, as one might expect, there are several manifestations of the overflow weir which perform various functions. A simple “standpipe” is a form of weir as is a fitting on the side of a tank located just below the desired liquid level. … Continued

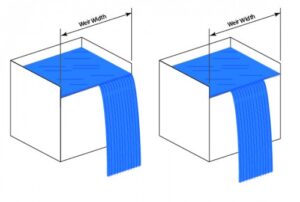

The concept and purposes of an overflow weir are pretty simple but making them perform for maximum benefit can be a challenge. For the best performance of a weir used in a skimming application, liquid should overflow the entire width of the weir. An area of stagnation is formed behind an area where there is no … Continued

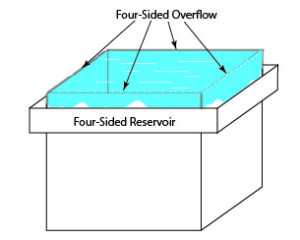

The final type of weir I’ll discuss in this series is the four-sided overflow weir in which liquid overflows all four sides of a process tank. This type of weir is normally found in equipment designed for “precision cleaning” applications and most commonly in rinses where efficient particle removal is a major consideration. The theory behind … Continued

I’ve made reference in the blog before to the fact that some surfaces are good candidates for ultrasonic cleaning while others are either difficult or impossible to clean. In general, surfaces that are hard (metal, glass) are easily cleaned using ultrasonics while softer surfaces (rubber, soft plastic) resist ultrasonic cleaning. The reason has to do … Continued

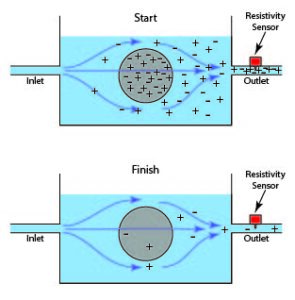

When a sound wave encounters an object or discontinuity in the sound conducting medium, at least part of the sound is reflected. The way the sound reflects depends in large part on the rigidity of the reflecting surface. If the object is hard, like a substantial piece of metal, the wave reflects as shown below. … Continued

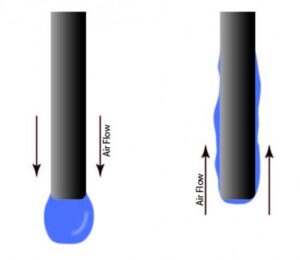

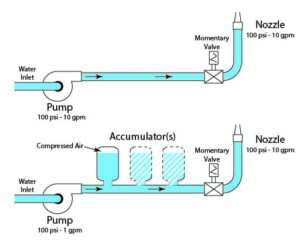

Drying is almost always the longest step in a cleaning process. Because of this, anything that will speed up the drying process is of special interest to the process engineer. Hot air drying is, by far, the most common means of drying used in the industrial parts cleaning arena. Major variables in hot air drying are temperature, … Continued

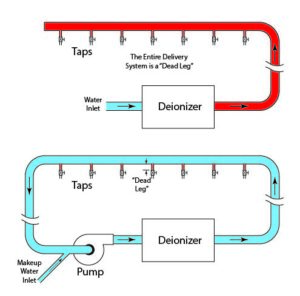

De-ionized water is commonly used in both industrial and precision cleaning systems, primarily for rinsing. De-ionized water is a little like the speed of light or absolute zero in that you can never quite TOTALLY remove all the ions from the water (although we can get close) and, once a certain level of de-ionization is achieved, it … Continued

As a prolog to the following let me just say, as I may have said before in this blog, that being an engineer is both a blessing and a curse. A blessing because you intuitively understand how things work (or at least think you do) that other people see as magic, and a curse because … Continued