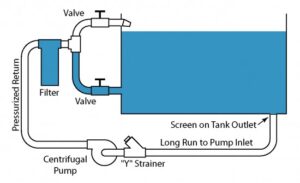

Let’s again look at the system schematic shown in the preceding blog. This time, however, it is shown with an “air lock.” The centrifugal pump, unable to pump air, is not able to move liquid to replace the air trapped in the plumbing system. At first glance, it may not be obvious how this condition … Continued

I have stressed the importance of temperature to cleaning processes many times in previous blogs. This blog will discuss the heat source options for achieving and maintaining the temperatures required for effective cleaning. Electric – Electric heat is, without a doubt, the most prevalent heat alternative used for cleaning applications. This is because electric heaters are relatively inexpensive, relatively small, … Continued

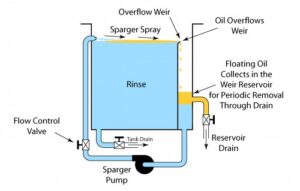

In the blogs Chemistry – Oil Splitting and Oil Emulsification – Part 1 and Chemistry – Oil Splitting and Oil Emulsification – Part 2, I discussed how oils are removed from parts using chemistry that either splits or emulsifies the oil. The next step is to collect and get rid of or recycle that removed oil. This … Continued

Surface cavitation erosion of ultrasonic transducers is a topic that users and manufacturers of ultrasonic equipment would often rather not talk about – – but we must. The erosion of a transducer surface due to surface cavitation is inevitable over time. Its severity depends on several factors, some of which can be controlled and some … Continued

When parts aren’t coming clean two of the first things most process engineers target as potential problems are the temperature and concentration of the chemistry. These are, in most cases, good bets but one should resist knee-jerk reactions. Chemical Concentration – One of the common knee-jerk reactions to a cleaning problem is to increase chemical … Continued

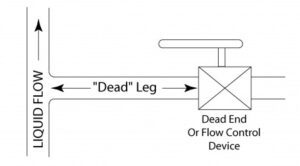

Just about everyone can recognize the benefits of sterilization to eliminate bio-burden in a plumbing system. Heat or chemicals toxic to living organisms are periodically introduced to kill the offending critters. This process can be conducted using either CIP (Clean In Place) or COP (Clean Out of Place) procedures. CIP simply means cleaning by flushing … Continued

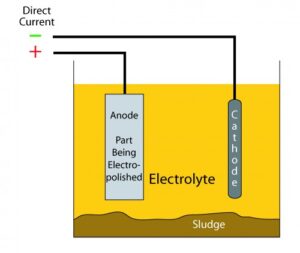

“Electropolishing,” (often shortened to E-P) is a term frequently heard in cleaning circles. Electropolishing of surfaces of cleaning equipment is employed to provide enhanced cosmetic appearance and, more importantly, to enhance their functionality. What is Electropolishing? – Electropolishing is a lot like electroplating except in reverse. In electropolishing, metal is removed rather than added as … Continued

As I have said before on this blog, I am not a chemist. Whatever I say about chemistry on the blog is expressed in layman’s terms and is based on practical experience and not on any deep understanding I have of the properties of chemicals. The usefulness of any information provided here applies only to … Continued

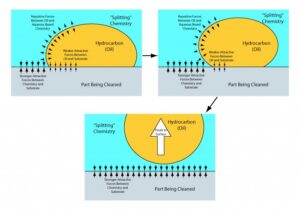

“Splitting” of oil from a surface as described in a preceding blog is a part of nearly any oil removal process. Note – Even cleaning chemistry that is generally classified as an “emulsifier” has ingredients to promote the initial “splitting” of the oil from the surface being cleaned. These ingredients are often called “surface active … Continued

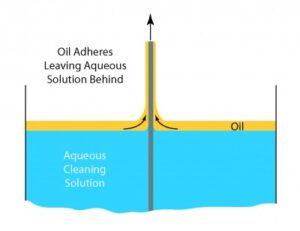

In some cases, previously described oil removal technologies based on the gravity separation of oil from the cleaning solution are unjustifiably cumbersome and expensive. Fortunately, smaller scale solutions are available for use in such applications. Oil Skimmers – Oil skimmers utilize a material which preferentially attracts oil (hydrophobic) to skim floating oil from a surface … Continued