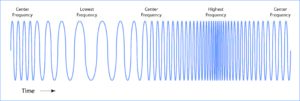

In today’s blog we once again bring ultrasonic sounds into the range of human audibility and listen to the sound of frequency sweep. Previous blogs have revealed the sound of amplitude modulation and pulse modulation. Frequency sweep is all about frequency – ideally there is no change in amplitude as frequency is varied. In some … Continued

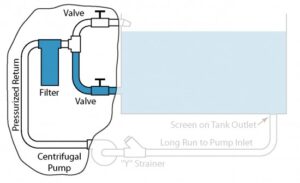

So, the goal is to get the air out of the system so that the pump can operate properly. In the preceding blog I explained what factors might keep air from escaping from the inlet side of the pump. It would, then, be a logical question to ask, “Why doesn’t the air just go out the … Continued

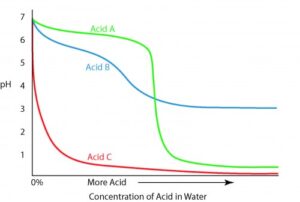

So far, we have recognized pH and specific gravity as ways to determine chemical concentration in cleaning solutions. This blog will explore additional techniques that may also be used for this purpose. Conductivity – Pure water is a poor conductor of electricity. As chemistry is added to water, it’s ability to conduct electricity is increased. … Continued

Previous blogs have revealed a number of ways to measure chemical concentration in a cleaning bath. It is a logical extension that process engineers utilize these tools to automate maintaining the proper chemical concentration in their cleaning processes. Overall, this is a great idea. However, there are some pitfalls and things that should be taken … Continued

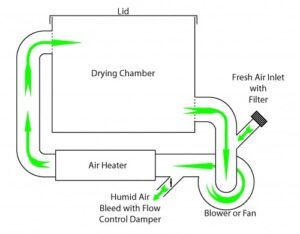

We have discussed earlier the importance of drying in a cleaning process. Despite the several hardware options available, hot air dryers remain the “go to” in industrial cleaning processes today. Today’s blog will discuss the basic design concept of hot air dryers and how they function. The main components of hot air dryers are a … Continued

I’ve always known that cleaning inside blind holes was a difficult task. In a previous blog, I demonstrated using video just how difficult it is to get liquids and/or air in and out of a blind hole. My plan was to approach the problem logically (largely based on intuition), and offer readers some solutions to … Continued

The movement of air is an important consideration in the design of most industrial cleaning systems. The immediate application that comes to mind is, of course, in drying. The movement of air is one of the major requirements for drying along with, of course, elevated temperature. In most cases, the need to move air in … Continued

At the urging of several readers I have decided to, from time to time, present a little puzzle or “thinking exercise” here on the blog. Maybe it will help those of us who are advancing in age to stave off the effects of Alzheimer’s disease or, better yet, just offer something to think about on … Continued

Cleanliness, as important as it is, is too often relegated to the final and “detached” stage in the process of product design. Even a very insightful design engineer seldom looks at a design from its conception with an eye to how this thing is going to be cleaned in the end. I suppose this is … Continued

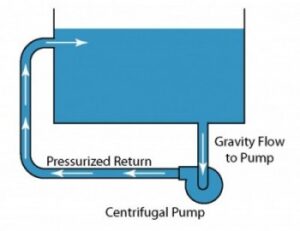

The blog Pumps – Centrifugal Pumps provided some basic information about the type of pump most commonly used in industrial cleaning equipment. Centrifugal pumps are simple, relatively inexpensive, versatile and reliable. However, as I mentioned in that blog, they do have some limitations. In order for a centrifugal pump to function, liquid to be pumped … Continued