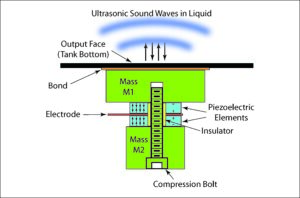

Preceding blogs have described the workings and principles of ultrasonic transducers. Today’s blog will summarize the information on piezoelectric ultrasonic transducers and give readers a view of what the real hardware looks like. An upcoming blog will concentrate on magnetostrictive hardware. Piezoelectric Transducers – Piezoelectric transducers, which may also be called electrostrictive transducers, nearly all … Continued

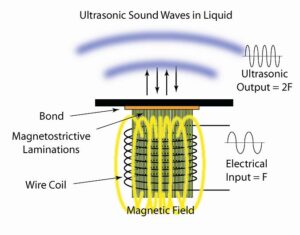

Today’s ultrasonic transducers utilize either the piezoelectric or magnetostrictive effect of materials to produce ultrasonic waves in liquids. This blog will concentrate on the magnetostrictive ultrasonic transducer. Magnetostrictive Transducers – Magnetostrictive ultrasonic transducers utilize the principle of magnetostriction exhibited by “ferromagnetic” materials which include iron, nickel and cobalt as well as many alloys of these … Continued

We all know, basically, what rust is and what causes it. What many don’t know, however, is that rust is unique in its properties. Knowing how to deal with and/or prevent rust is very important in many cleaning applications. The above picture is actually worthy of hanging on a wall as art. In fact, I … Continued

In the blogs about transducers I made a point of telling readers that an ultrasonic transducer must be driven at its resonant frequency to achieve optimum performance. What I didn’t address, however, was the fact that the resonant characteristics of a transducer can be varied by its design. Not only the resonant frequency but the “sharpness” or “Q” … Continued

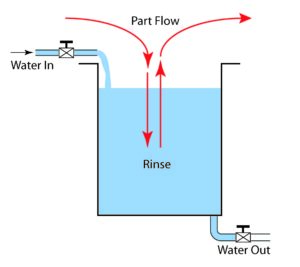

Rinsing as it applies to aqueous parts cleaning is a final “cleaning” step which removes residues introduced by or resulting from the primary cleaning process. There are several options to choose from when it comes to rinsing. Making the proper selection is very important to the overall cleaning process as the final rinse inevitably defines overall cleanliness. … Continued

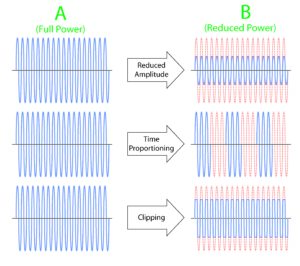

Many ultrasonic generators are configured to operate at one power level – full on. There are occasions, however, when controlling the ultrasonic power is critical to a successful ultrasonic cleaning process. This is especially true when cleaning parts made of relatively soft materials including brass, copper and, in some cases, even aluminum. Other cases requiring … Continued

Certain benefits can be derived in ultrasonic cleaning and processing by “pulsing” the ultrasonic generator. In fact, different pulse rates and duty cycles produce different benefits. This blog explores how “pulse” works and how its variants benefit ultrasonic cleaning in different ways. An earlier blog described the basic function of the ultrasonic generator. Ultrasonics – Ultrasonic Generator … Continued

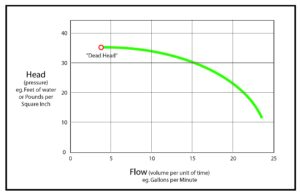

A rose is a rose is a rose. But pumps, now that’s a different thing. Pumps, even though they may look physically the same, can vary significantly in their ability to pump liquids under various conditions. In order to know how a pump will perform in a particular application, one must rely on something called … Continued

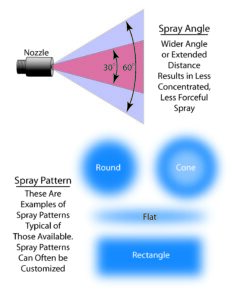

Previous blogs have suggested the use of liquid sprays in air as either a primary mechanism or as an enhancement to both cleaning and rinsing operations. Today’s blog will discuss, briefly, what is important in choosing a spray nozzle or nozzles for a particular application. In order for spray to be effective, of course, the … Continued

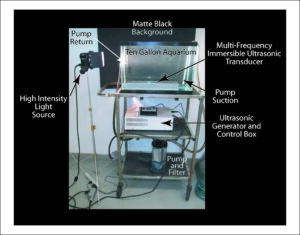

It occurred to me several years ago that when we look at an ultrasonic cleaning tank, we are usually looking in from the top. I wondered how ultrasonics looked from a “fish eye” view which spawned (get it?) what is now called the ultrasonic fish tank in our Jamestown, NY laboratory. In upcoming blogs, I … Continued